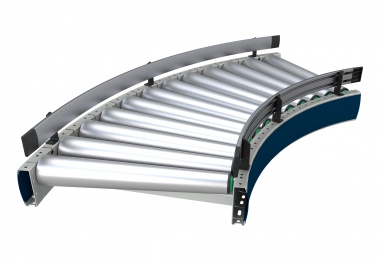

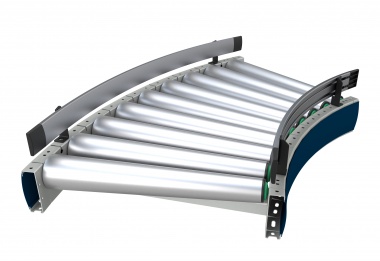

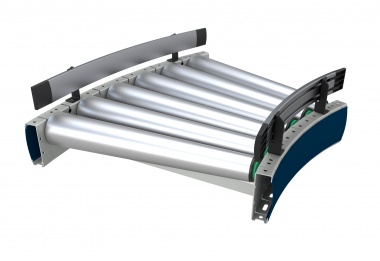

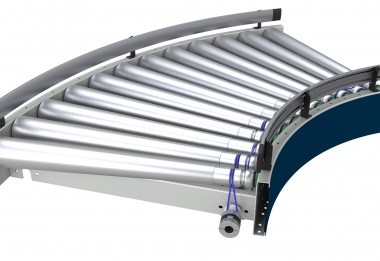

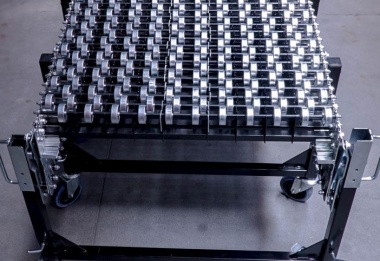

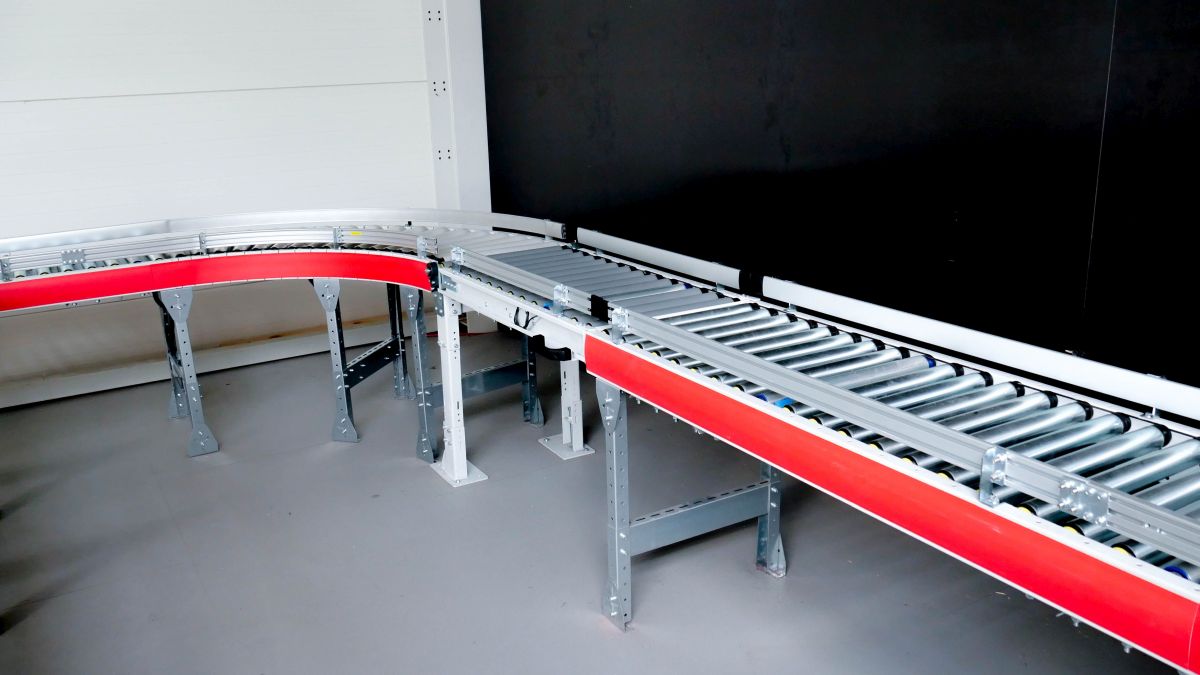

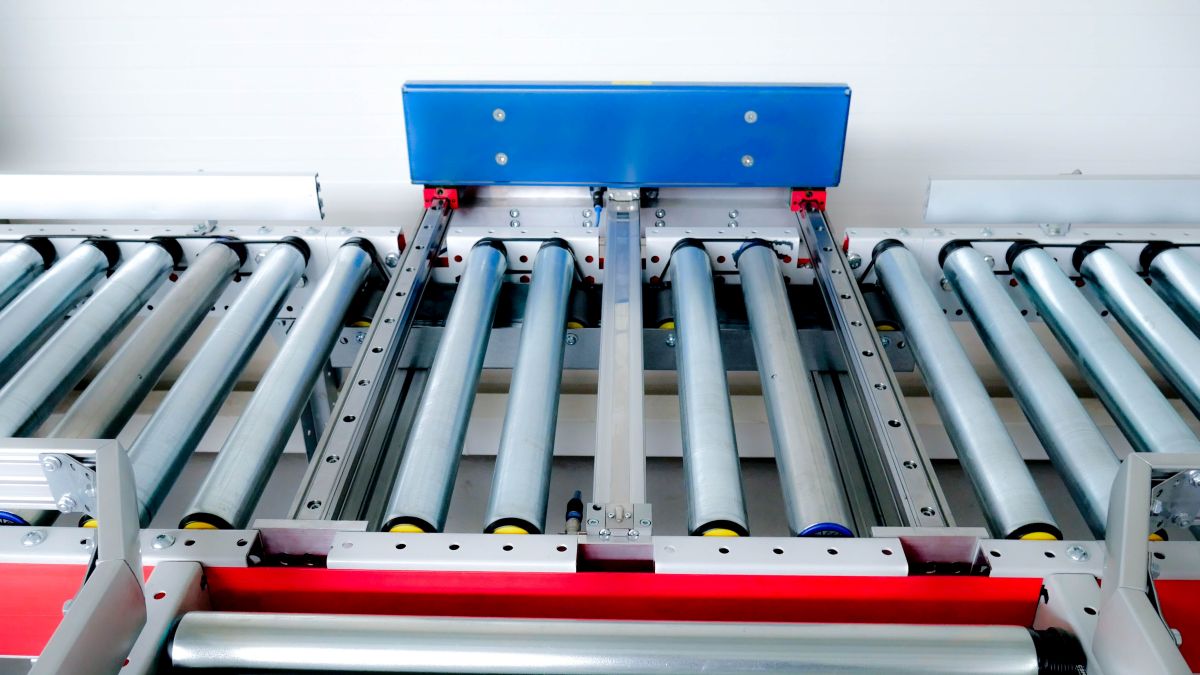

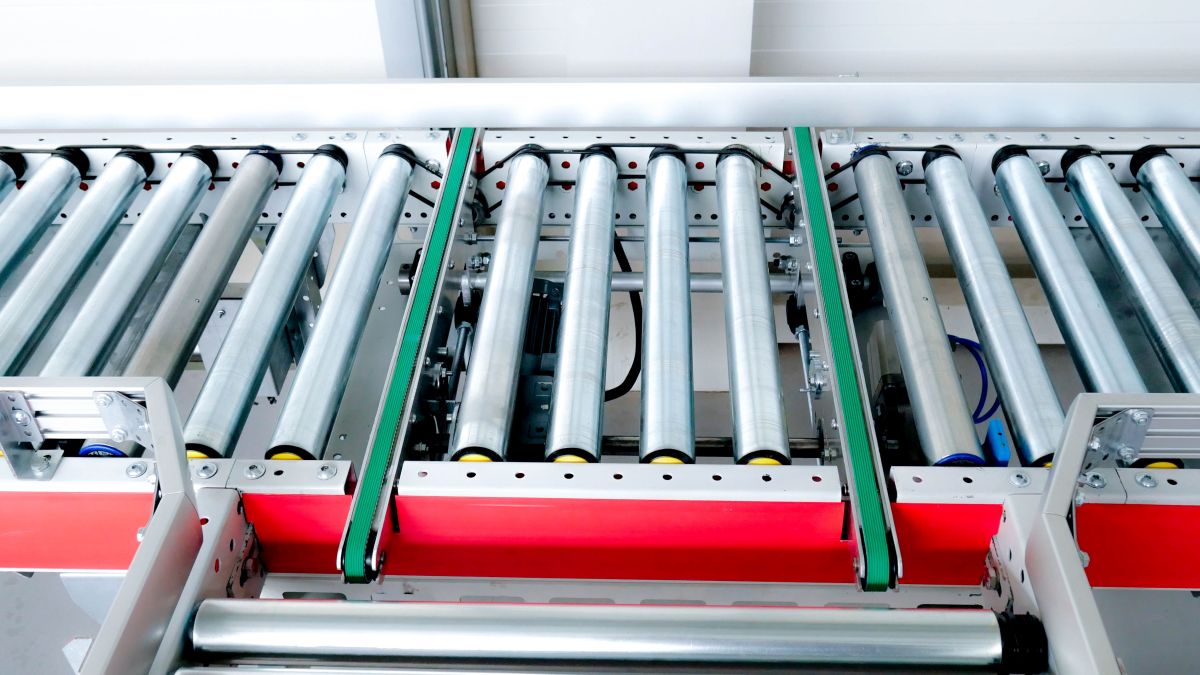

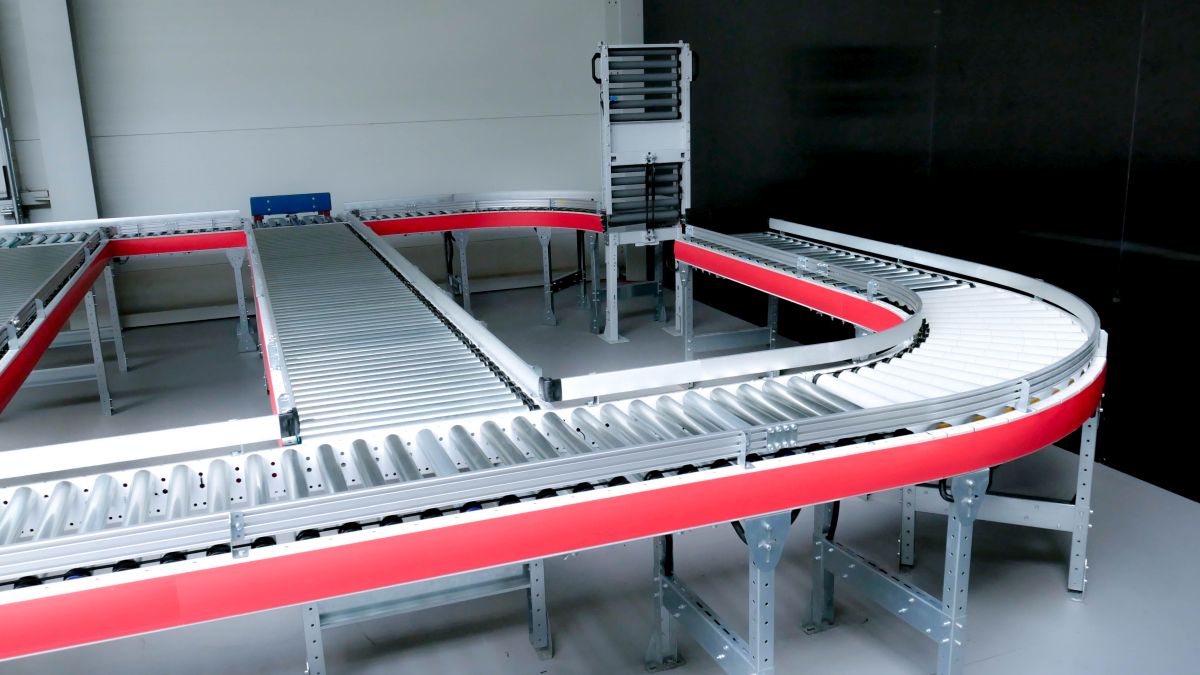

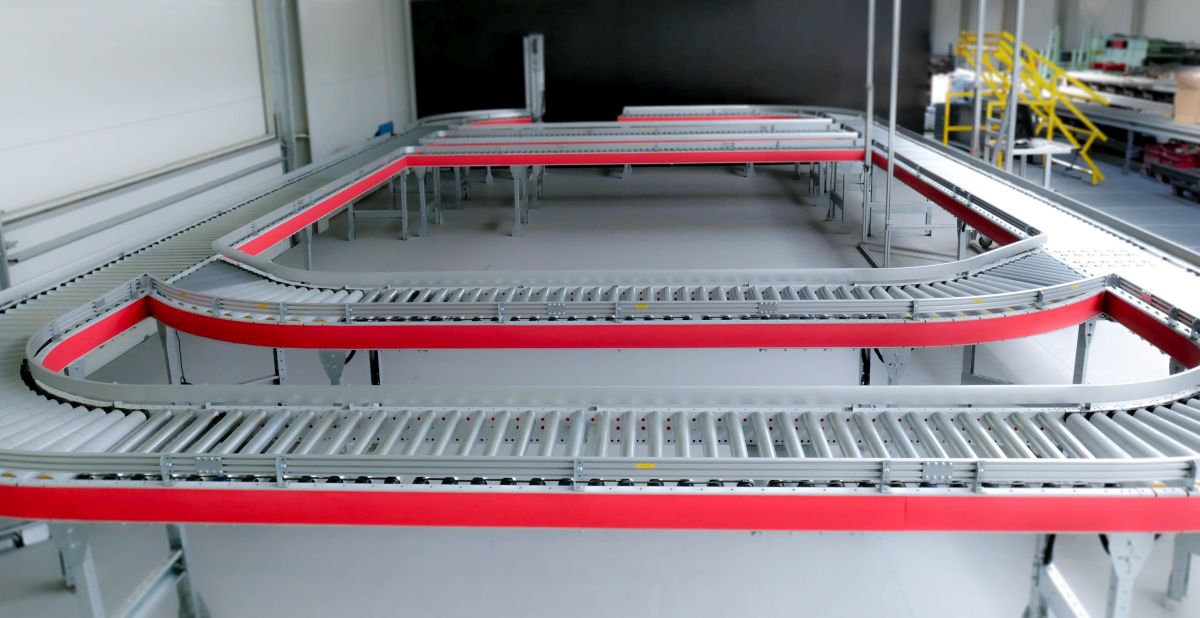

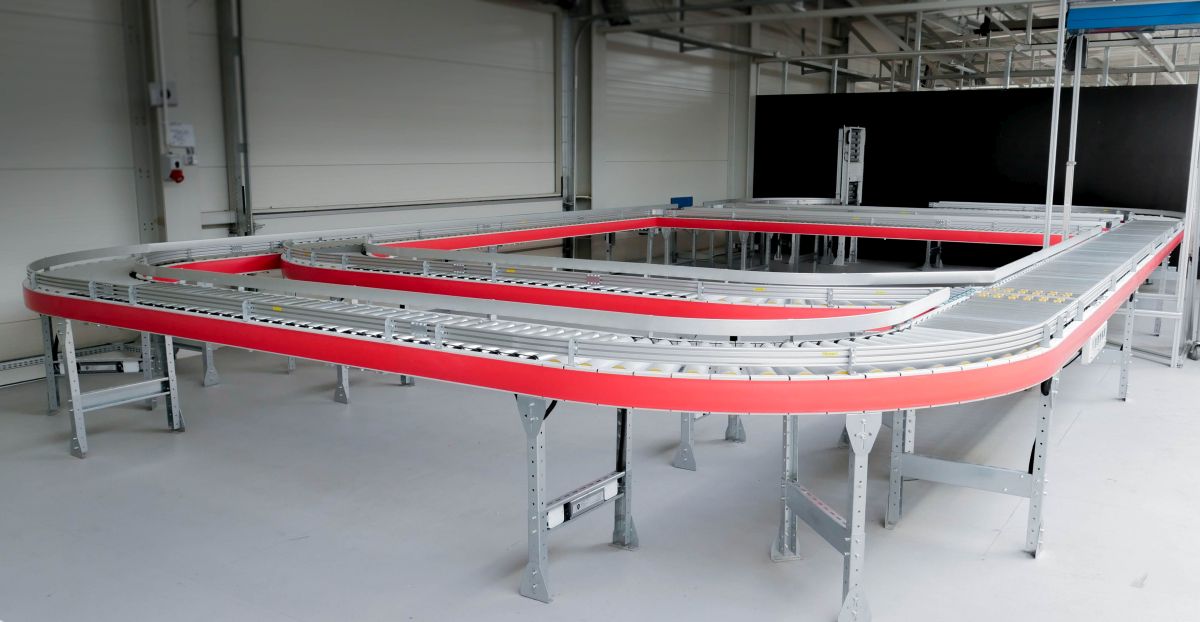

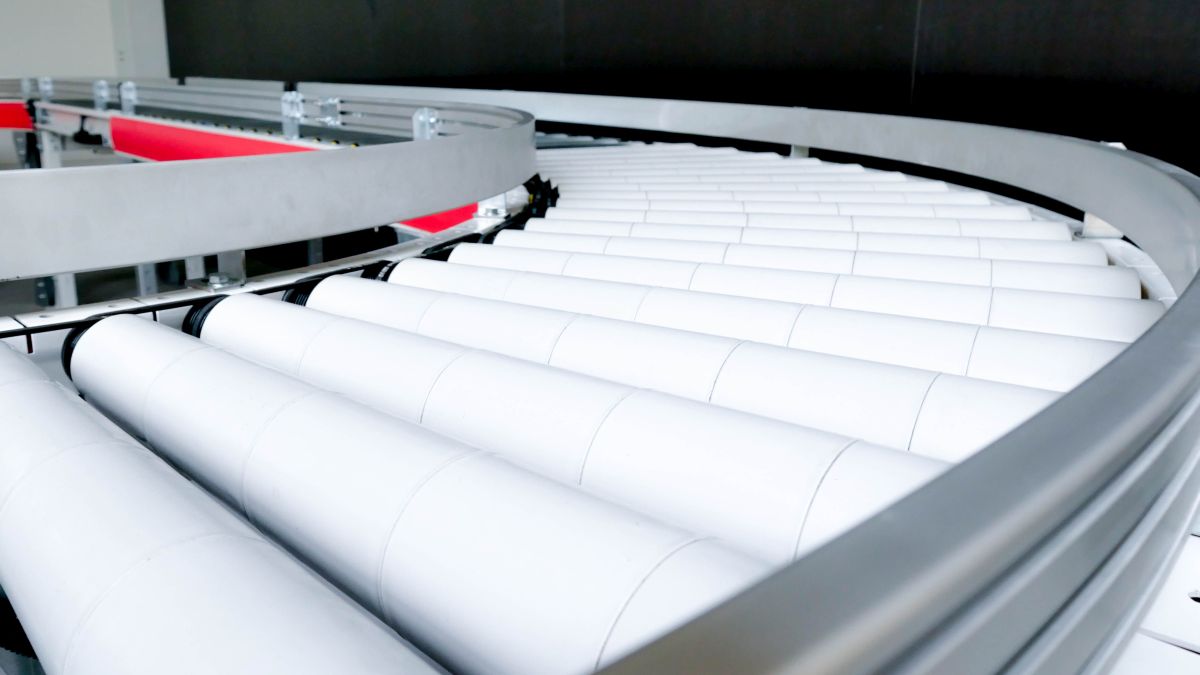

Roller conveyors

Roller conveyors are another very popular range of conveyors. Thanks to specially designed aluminum profiles, they are used for transporting elements of relatively small mass, as well as heavy elements, e.g. pallets, boxes, containers, wooden boards, etc. The main transport element is a steel roll. The use of precision bearings ensures long and trouble-free operation. The modularity of these feeders and the special construction allows quick installation of additional devices and other accessories. Feeders are made in various lengths, widths and graduations, thanks to which you any transport lines based on arcs, angular entrances, transversal transfers and gravity conveyors can be built. The electro-roll is the most commonly used in roller conveyors. Together with the controller and the superior PLC control system, we have the ability to build conveyors without pressure-sensitive and fully automatic close-haul lines.

Tape conveyors

Tape conveyors are used in many branches of industry. They are designed for small and medium loads such as car tyres, cartons, boxes. The construction of the feeder is made of specially selected aluminium or steel profiles. The drive is implemented by high-quality motor reducers or electro-drums. The conveyor tape, appropriately selected for the transported material, slides on the worktop with a low coefficient of friction, increasing its life. Conveyors are built in the form of universal modules that give many possibilities while creating comprehensive transport lines.

Belt conveyors

Belt conveyors are used in the transport of elements of large dimensions and relatively small mass, such as: polystyrene, mineral wool, etc. The drive system includes a motor reducer and the transport element mainly consists of long-life belts.